Ellantra Automation Pvt Ltd

Ellantra Automation Pvt Ltd

Objective : implement strategies for improving Overall Equipment Effectiveness (OEE) across production lines.

Challenges faced :

1) Downtime and Efficiency: Inconsistent equipment uptime resulted in significant downtime, impacting overall production efficiency.

2) Performance Disparities: Variations in machine speeds and performance led to inconsistencies in output quality and quantity.

3) Maintenance Management: Reactive maintenance practices led to increased breakdowns, affecting production schedules and causing revenue losses.

4) Resource Allocation: Inefficient resource utilization due to lack of real-time data on equipment performance.

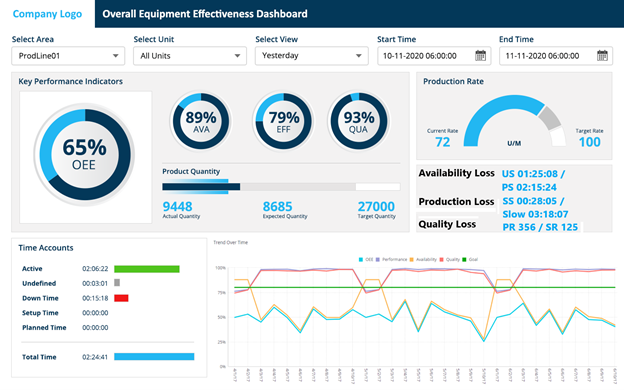

OEE Assessment: Conducted a comprehensive assessment of existing equipment to identify areas for improvement in OEE.

Data Collection Systems: Implemented IoT sensors and data collection systems to gather real-time equipment performance data.

Analytics and Monitoring: Utilized data analytics to monitor and analyze OEE metrics, including availability, performance, and quality.

Predictive Maintenance: Developed predictive maintenance models to proactively identify and address potential equipment failures.

Training and Integration: Provided training to the staff for seamless integration of OEE optimization practices into their workflow.

Assessment Phase: Conducted a thorough analysis of equipment performance, downtime, and production inefficiencies.

Sensor Integration: Installed IoT sensors and data collection systems across machinery and production lines.

Data Analytics Setup: Established a robust analytics platform to collect, process, and visualize OEE metrics in real-time.

Predictive Maintenance Models: Implemented machine learning algorithms to predict potential equipment failures and schedule proactive maintenance.

Employee Training: Conducted workshops and training sessions to familiarize staff with OEE concepts and best practices.

Improved Equipment Uptime: Increased overall equipment availability by 20%, minimizing unplanned downtime.

Cost Savings: Proactive maintenance strategies reduced maintenance costs by 25% through fewer breakdowns and repairs.

Enhanced Performance: Optimized equipment performance led to a 15% increase in production speed and consistency.

Resource Optimization: Better resource utilization and scheduling increased operational efficiency by 30%.

Are You Impressed With Our Amazing work?

© 2024 Copyright Ellantra Automation Pvt Ltd